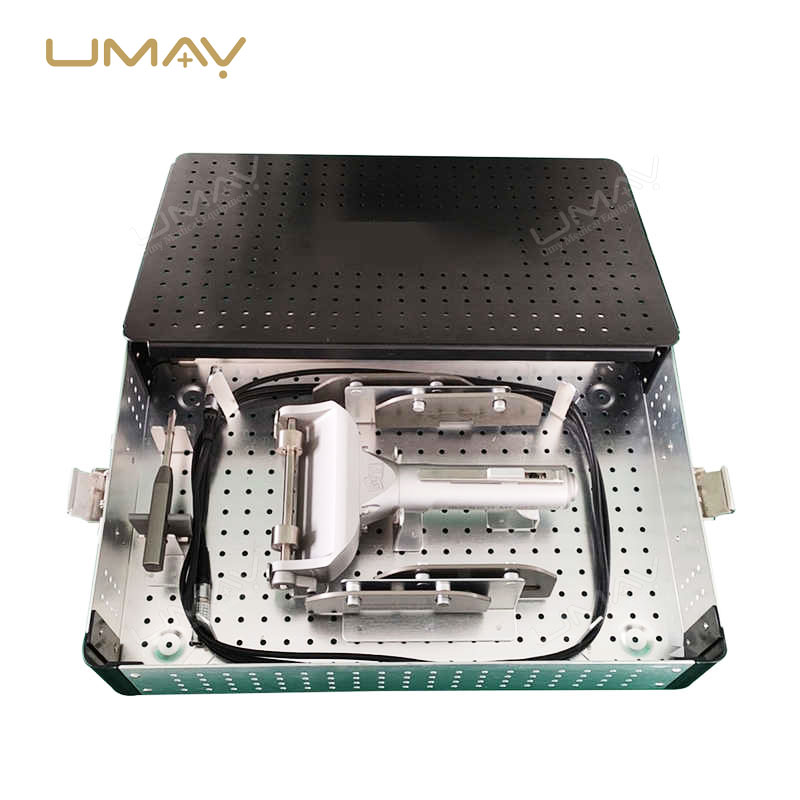

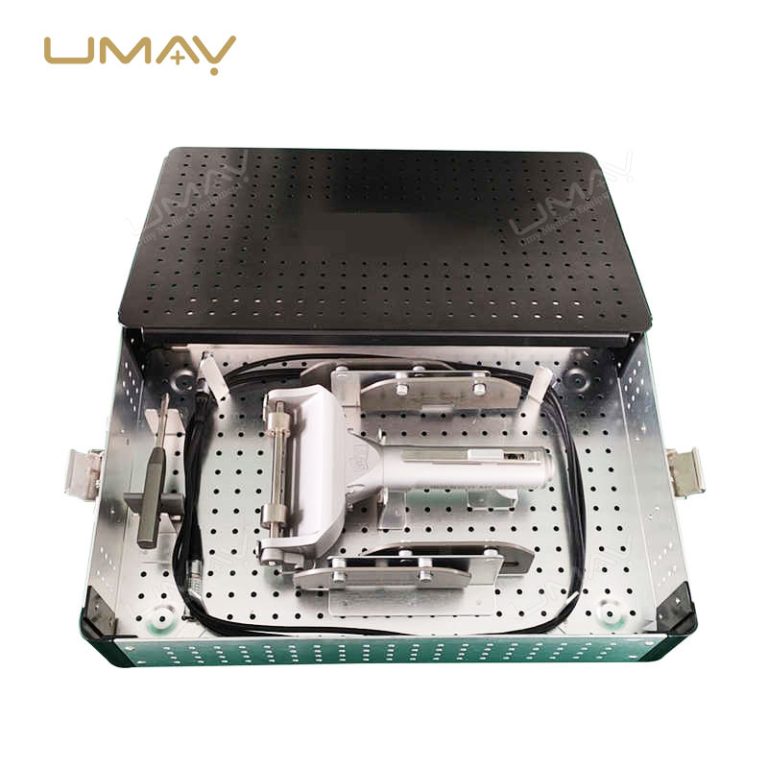

Electric Dermatome for Skin Grafting in Burn and Plastic Surgery

Quick Info.

Power Source: Electric

Warranty: 1 Year

After-sale Service: Online technical support

Material: Metal, Plastic, Medical Stainless Steel

Instrument Classification: Class II

Safety Standard: GB9706.1-2007

- SKU NO.: UMY-EN-051

- Warranty: 1 Year

- Origin: China

The Electric Dermatome is designed for precision skin grafting in burn and plastic surgery, offering reliable and consistent results. This advanced device allows for controlled, even thickness of skin removal, improving the outcome of grafting procedures. It is ideal for use in both burn care and reconstructive surgeries, enabling surgeons to efficiently harvest grafts while minimizing patient trauma. The ergonomic design ensures ease of use, enhancing surgical workflow. With its high performance and durability, the Electric Dermatome is a trusted tool for enhancing recovery and results in skin grafting procedures.

The Specific Parameters

| ITEMS | PARAMETERS |

|---|---|

| Power | |

| Power | 220V ~ 50Hz |

| Motor Power | 40W |

| Motor | |

| Motor Type | Miniature Brushless DC Motor |

| Speed | 0 ~ 6500RPM |

| Blade | |

| Blade Type | Imported Medical Stainless Steel |

| Thickness | 0.05-0.75 mm (adjustable) |

| Blade Width | 1 inch (2.5cm), 1.5 inch (3.8cm), 2 inch (5.1cm), 3 inch (7.6cm), 4 inch (10.2cm) |

| Thickness Adjustment | Adjustable via micro knob, 0.05mm per dial ( OEM customizable range 0-1.6mm) |

| Working Mode | Foor Switch / Manual Double Switch |

Skin Graft Thickness Adjustment

Adjustable range: 0–0.75 mm in increments of 0.05 mm.

Unilateral thickness adjustment button ensures high stability and eliminates the need for zero calibration.

Skin Graft Width Options

Available widths: 2.5 cm, 5.1 cm, 7.6 cm, and 10.2 cm (4 standard width plates included).

Custom width plates can be manufactured upon request to meet specific surgical requirements.

Blade Features

– Self-lubricating blade for smooth operation.

– Easy blade loading and unloading mechanism.

– Smooth reciprocating motion to prevent metal-to-metal contact and ensure precision.